Rewire Condenser Fan Motor Frigidaire FFSS2615TS

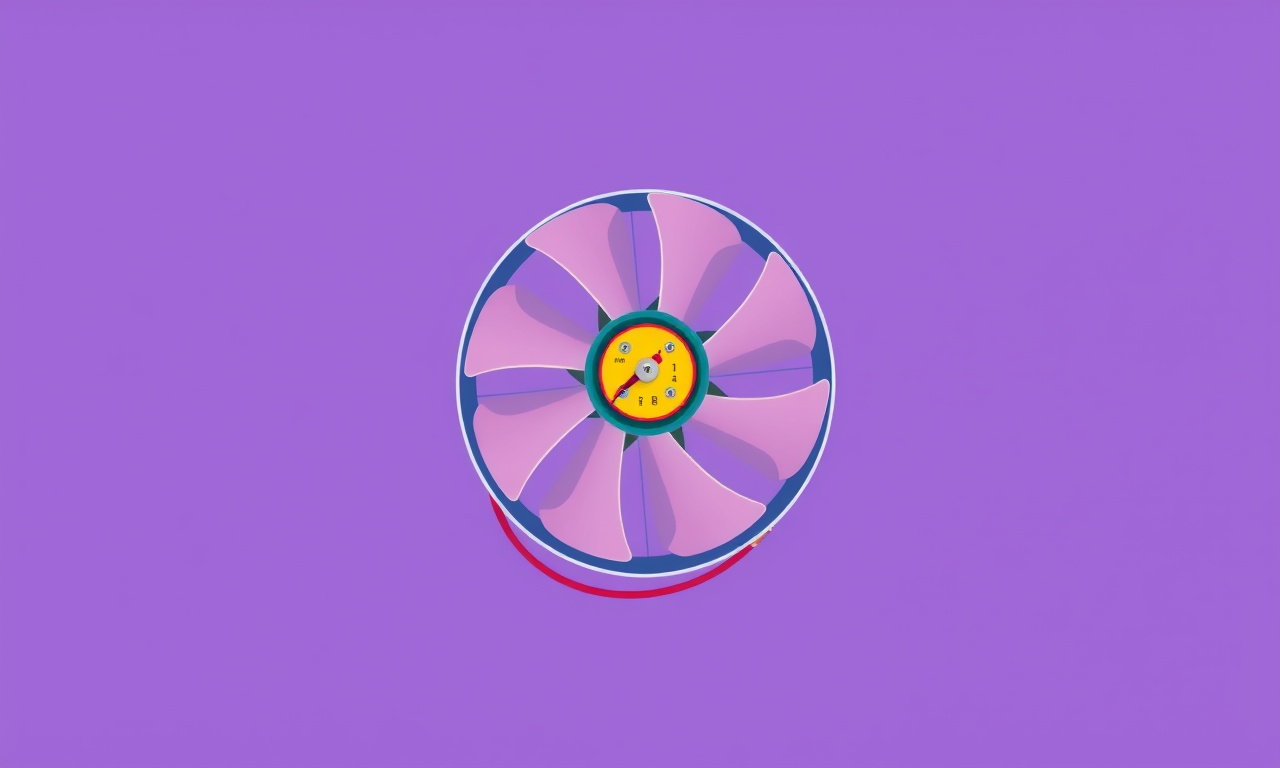

Introduction

The condenser fan motor in a Frigidaire FFSS2615TS refrigerator is the heart of the cooling cycle. Over time it can develop electrical issues that lead to a noisy or dead fan, reduced efficiency, or a total failure of the compressor. One common repair is rewiring the fan motor, which can restore proper operation without the need for a costly replacement. This guide walks you through every detail of the process—from safety precautions to the final test run—so you can confidently tackle the job in your own garage or living room.

Why Rewire the Condenser Fan Motor?

When a fan motor stops running or spins at an incorrect speed, the culprit is often an electrical fault: a bad connection, a broken terminal, or a damaged wiring harness. Rewiring addresses these problems by:

- Restoring proper voltage and current flow

- Eliminating loose or frayed contacts

- Replacing damaged wires with new, rated conductors

- Providing a long‑term fix rather than a temporary fix

If the motor itself is burnt or the fan blades are warped, rewiring alone will not solve the issue. In that case you’ll need a new motor or fan assembly. However, if you’re dealing with a simple wiring failure, rewiring can bring your fridge back to life.

Safety First

Before you start any electrical work on your refrigerator, follow these precautions:

- Turn Off Power – Switch off the appliance at the circuit breaker.

- Unplug the Unit – If you prefer, disconnect the power cord from the outlet.

- Allow Cooling – Give the fridge a few minutes to cool so you don’t touch hot components.

- Use Insulated Tools – Protect yourself against accidental shocks.

- Work in a Dry Environment – Keep the area free of moisture.

Failing to observe these safety steps can result in injury or a fire hazard.

Tools and Materials You’ll Need

| Item | Purpose |

|---|---|

| Non‑contact voltage tester | Verify that the unit is de‑energized |

| Screwdrivers (Phillips and flathead) | Remove panels and fasteners |

| Needle‑point pliers | Grip small terminals |

| Wire stripper and cutter | Strip insulation and cut new wire |

| Heat‑shrink tubing (10‑12 mm) | Insulate connections |

| Soldering iron with solder | Create secure, permanent joints |

| Electrical tape | Add a layer of protection |

| New 12‑AWG or 14‑AWG copper wire | Replace damaged strands |

| Voltage tester or multimeter | Check continuity and voltage |

| Labeling tags | Mark new connections for future reference |

Having the correct gauge wire is essential. The motor in the FFSS2615TS typically uses 12‑AWG copper conductors. If you are unsure, consult the service manual or a professional.

Step‑by‑Step Rewiring Process

1. Locate the Condenser Fan Motor

The condenser fan motor is usually mounted on the back panel of the refrigerator, near the rear compressor. To access it:

- Remove the rear access panel of the fridge.

- Disconnect any wiring harnesses that attach to the motor housing.

- Note the orientation of the motor and its terminals.

2. Identify Faulty Wiring

Use a multimeter or a non‑contact voltage tester to check each terminal:

- Set the meter to AC voltage (120 V).

- Measure the voltage between the power terminal and the ground.

- Check for continuity between the motor windings.

If you find a terminal with no voltage or an open circuit, mark that connection for replacement.

3. Strip the Old Wire

Once you’ve identified which wire(s) need replacement:

- Use a wire stripper to remove about 1.5 cm (¾ inch) of insulation from the end.

- Twist the exposed copper strands to ensure they are not frayed.

- Remove any debris or oxidation with a clean cloth.

4. Prepare the New Wire

- Cut a piece of fresh copper wire that is slightly longer than the old one.

- Strip 1.5 cm of insulation from both ends.

- Fold each end into a small hook to aid in soldering.

- Slide a length of heat‑shrink tubing onto each end before soldering.

5. Solder the Connection

- Position the new wire against the terminal on the motor.

- Heat the joint with a soldering iron.

- Apply solder to the copper, allowing it to melt into the joint.

- Remove heat, let the joint cool, and slide the heat‑shrink tubing onto the soldered spot.

- Warm the tubing with a heat gun or lighter until it shrinks snugly over the connection.

This technique provides a strong, long‑lasting bond that resists vibration.

6. Reattach the Motor

- Slide the motor back into its mount, aligning it with the mounting holes.

- Secure the motor with screws or bolts.

- Re‑connect any harnesses you removed earlier, making sure the wires are firmly seated.

7. Test the Motor

- Re‑turn the power back on at the breaker.

- Use the multimeter to verify that the correct voltage (120 V) reaches the motor’s power terminal.

- Observe the fan for proper rotation speed and direction.

- Check for unusual noises or vibrations.

If the motor still does not operate, double‑check your soldered connections, ensure all terminals are tight, and confirm that you have used the correct wire gauge.

8. Final Inspection

- Inspect all connections for signs of overheating or loose contacts.

- Apply electrical tape over the heat‑shrink tubing to add a protective layer.

- Replace the rear access panel and any other panels you removed.

- Secure the refrigerator in place and reconnect it to the kitchen layout.

Common Issues and How to Resolve Them

| Symptom | Likely Cause | Quick Fix |

|---|---|---|

| Fan motor runs slowly | Voltage drop | Rewire with correct gauge, check supply |

| No sound from fan | Broken terminal or open circuit | Inspect terminal, replace wire |

| Fan spins erratically | Loose connection or vibration | Tighten screws, secure with lock‑nuts |

| Motor overheats | Shorted windings | Check continuity, replace motor if necessary |

If you encounter any of these problems during testing, repeat the appropriate step from the guide or seek professional assistance.

Tips for a Successful Rewire

- Label Everything – Use clear markers on new wires so future maintenance is easier.

- Keep Wires Neat – Avoid tangled or overlapping strands; this reduces heat buildup.

- Verify Polarity – Though the fan motor is AC, ensure that the positive and negative ends are correctly matched if the motor has specific orientation requirements.

- Use Adequate Heat Shrink – Shrink all soldered joints to eliminate exposed conductors.

- Double‑Check Grounding – Proper grounding protects the motor and prevents electric shock.

When to Replace the Motor Instead

Rewiring is a viable solution only when the motor windings themselves are intact. Signs that you need a replacement include:

- A burning smell or visible scorch marks.

- Discoloration of the motor housing.

- Failure to run even after rewiring.

- An audible “click” or “pop” when the motor attempts to start.

In those cases, obtain a compatible replacement motor from a reputable supplier and follow the manufacturer’s installation guide.

Conclusion

Rewiring the condenser fan motor on a Frigidaire FFSS2615TS refrigerator is a practical and cost‑effective way to restore cooling performance when the issue lies with the wiring rather than the motor itself. By following the safety guidelines, gathering the right tools, and carefully following the step‑by‑step instructions, you can eliminate downtime and keep your fridge running smoothly.

Remember to test your work thoroughly, double‑check connections, and maintain proper labeling for future reference. With a little patience and attention to detail, you’ll have your refrigerator humming again in no time.

Discussion (5)

Join the Discussion

Your comment has been submitted for moderation.

Random Posts

Reassessing the Audio Jack Dropout on LG Velvet 2

Explore why the LG Velvet 2's 3.5mm jack glitches, what triggers audio dropouts, user fixes, and LG's stance: essential insight for current and future Android phones.

1 year ago

Philips HP700 Fan Stalls Quietly Even At Low Speed Why This Happens And What To Do

Discover why your Philips HP700 quietly stalls at low speed, spot early signs, and fix the issue to keep steady airflow.

2 weeks ago

How to Stop Sharp LC-40M from Producing Audio Sync Issues While Gaming

Fix your Sharp LC-40M so game audio stays in sync. Learn quick settings tweaks, cable checks, and audio-output fixes that keep sound matching action for a flawless gaming experience.

6 months ago

Solve Arlo Pro 4 Wireless Connection Problems

Discover quick fixes for offline Arlo Pro 4 cameras. Check power, Wi, Fi, firmware, reset steps, and more get your live feed back up fast.

4 months ago

Panasonic D45 Dryer Timer Skips Final Drying Cycle

Discover why your Panasonic D45 dryer skips its final cycle, learn the symptoms, root causes, and easy fixes to keep clothes dry, save energy, and avoid extra runs.

5 months ago

Latest Posts

Fixing the Eufy RoboVac 15C Battery Drain Post Firmware Update

Fix the Eufy RoboVac 15C battery drain after firmware update with our quick guide: understand the changes, identify the cause, and follow step by step fixes to restore full runtime.

5 days ago

Solve Reolink Argus 3 Battery Drain When Using PIR Motion Sensor

Learn why the Argus 3 battery drains fast with the PIR sensor on and follow simple steps to fix it, extend runtime, and keep your camera ready without sacrificing motion detection.

5 days ago

Resolving Sound Distortion on Beats Studio3 Wireless Headphones

Learn how to pinpoint and fix common distortion in Beats Studio3 headphones from source issues to Bluetooth glitches so you can enjoy clear audio again.

6 days ago