Replacing Control Board on Vapir L+ Steam Cleaner

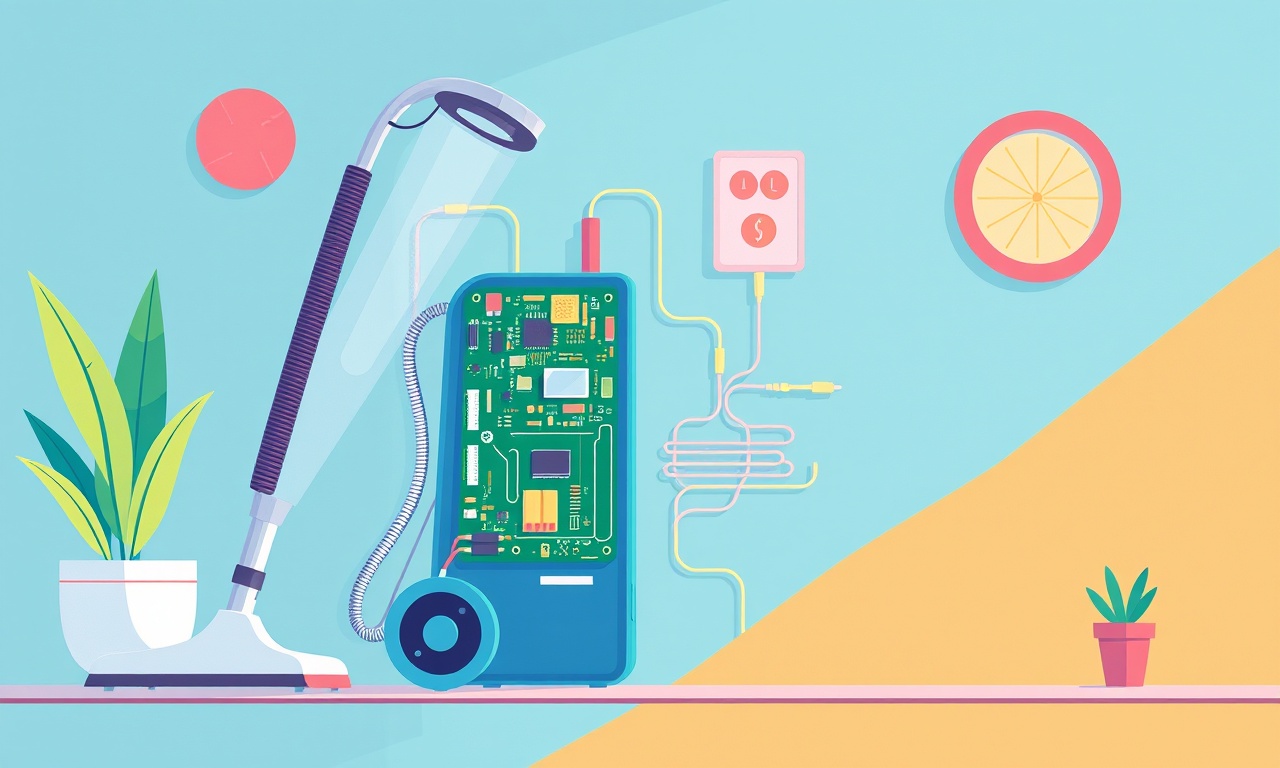

Replacing the Control Board on a Vapir L+ Steam Cleaner

A malfunctioning control board can render a Vapir L+ Steam Cleaner useless. While the unit is designed for easy operation, many users are not aware that the control board—often the brain of the machine—can be replaced with a few basic tools and a little patience. The following guide walks you through every step, from safety precautions to troubleshooting, ensuring that your cleaner runs like new again.

Why You Might Need a New Control Board

The control board manages temperature regulation, pressure control, and safety interlocks. Common symptoms of a failed board include:

- No power or intermittent power when the unit is turned on.

- The heating element fails to ignite.

- The device shuts off unexpectedly during operation.

- The indicator lights flicker or remain off.

If you have tried resetting the unit, checking the power cable, and verifying the water supply, a replacement board is likely the solution.

Tools and Materials

| Item | Description |

|---|---|

| Phillips‑head screwdriver | For removing screws. |

| Flat‑head screwdriver | For prying panels or separating components. |

| Hex keys (1.2 mm, 1.6 mm) | Some panels are secured with hex screws. |

| Anti‑static wrist strap | Protects electronic components from electrostatic discharge. |

| Replacement control board (OEM part number 201-005) | Ensure you have the correct model for the Vapir L+. |

| Contact cleaner (optional) | For cleaning connector pins if they appear dirty. |

| Work surface with good lighting | A clean, well‑lit area aids visibility. |

Safety First

- Disconnect the Power – Unplug the unit from the outlet. The Vapir L+ contains high voltage components, and accidental energization can cause serious injury.

- Drain the Water Reservoir – Remove any remaining water to prevent spills when the unit is opened.

- Ground Yourself – Wear the anti‑static wrist strap or touch a grounded metal object before handling the board.

- Work on a Flat, Stable Surface – Prevent the unit from tipping or slipping during disassembly.

Preparing for Disassembly

- Locate the Control Board – It is situated behind the main control panel, usually near the bottom of the unit.

- Remove the Front Panel – Gently pull the front panel outward until the rubber gasket snaps back.

- Unscrew the Panel Fasteners – A Phillips screwdriver will remove the screws that hold the panel in place. Keep the screws in a labeled container so you know which goes where later.

- Disconnect Power Cables – The board will be connected to a few ribbon cables. Carefully unplug each one by pulling on the connector tab, not the cable.

- Label the Cables – Use masking tape or small sticky notes to label each connector. This will help re‑connect them correctly after the new board is installed.

Removing the Old Control Board

Step 1 – Detach the Board

Once the panel is off, the control board will be visible. It is typically held by a small number of screws or a single mounting bracket. Remove any screws or release the bracket gently.

Step 2 – Inspect for Damage

Look for signs of burnt components, cracked solder joints, or corrosion. If you notice any of these, the board is confirmed dead and should be replaced.

Step 3 – Clean the Board

If you plan to reuse the board for troubleshooting, clean the solder pads with isopropyl alcohol and a cotton swab. Do not leave residue on the board.

Step 4 – Remove the Board

Carefully lift the board out of its socket, avoiding any strain on the connectors. Place it in a static‑safe bag if you intend to keep it for diagnostics.

Installing the New Control Board

- Place the New Board – Align it with the mounting holes and insert it gently into the socket.

- Secure the Board – Reattach any screws or brackets that hold the board in place. Tighten them just enough to hold the board but avoid overtightening.

- Reconnect Power Cables – Using the labels you created earlier, plug each ribbon cable back into its corresponding connector on the new board.

- Verify Connections – Double‑check that all connectors are seated firmly. A loose cable can cause the unit to behave unpredictably.

- Reassemble the Front Panel – Slide the panel back onto the unit until the gasket clicks into place. Replace the screws and tighten them.

Power‑On Testing

- Restore Water Reservoir – Fill the reservoir with fresh water.

- Plug In the Unit – Connect the power cord back to the outlet.

- Turn On the Cleaner – Switch the power button to ON. Observe the indicator lights.

- Check Heating – The heating element should activate, and the unit should build up pressure.

- Run a Short Test Cycle – Operate the cleaner for a minute or two to ensure stable temperature and pressure.

If the unit powers on, heats correctly, and maintains pressure, the replacement was successful. If any issues persist, refer to the troubleshooting section.

Troubleshooting Common Problems

| Symptom | Likely Cause | Fix |

|---|---|---|

| Unit won’t power on | Loose connection or mis‑aligned board | Re‑check all connectors; ensure board seated correctly |

| No heat or low temperature | Faulty thermostat or heater element | Test the heater element with a multimeter; replace if necessary |

| Rapid pressure loss | Valve seal or sensor failure | Inspect the valve; replace the pressure sensor if defective |

| Indicator lights flicker | Bad solder joints or dirty contacts | Clean the board contacts with contact cleaner; re‑solder if needed |

If after these steps the cleaner still does not function, the issue may lie beyond the control board—perhaps in the water pump or the heating element—and a professional service may be required.

Tips for a Smooth Replacement

- Keep a Clean Workspace – Small screws can get lost in clutter. Work on a surface with a magnetic mat or a container that catches loose parts.

- Take Photos During Disassembly – A quick picture of each disassembled component helps during reassembly.

- Label Everything – Even if you have labeled connectors, marking the orientation of the board and its screws can prevent confusion.

- Avoid Over‑Tightening – Tight screws can crack plastic housings; use a gentle, even torque.

- Respect the Warranty – If your Vapir L+ is still under warranty, opening the unit may void it. Contact the manufacturer first.

Frequently Asked Questions

Can I use a third‑party control board?

OEM boards are recommended for reliability and safety. Third‑party boards may not match voltage or timing requirements and can pose risks.

Will a new board fix a leaking water reservoir?

No. The control board governs heating and pressure, not the physical integrity of the reservoir. Check for cracks or loose seals separately.

How long does a replacement take?

With proper tools and experience, the entire process can be completed in 30–45 minutes.

Do I need to recalibrate the unit after replacement?

Most Vapir L+ models do not require recalibration. The board’s firmware manages temperature and pressure automatically.

Final Thoughts

Replacing the control board on a Vapir L+ Steam Cleaner is a manageable DIY task when approached methodically. By following the steps outlined above—prioritizing safety, preparing adequately, and taking your time—you can restore your cleaner to full working order without the cost of a professional repair or a brand‑new machine.

Enjoy the convenience of a freshly functioning steam cleaner and the peace of mind that comes from having solved a technical challenge yourself.

Discussion (8)

Join the Discussion

Your comment has been submitted for moderation.

Random Posts

Addressing Apple iPhone 14 Pro Max Battery Drain During Gaming Sessions

Learn why iPhone 14 Pro Max batteries drain during gaming, how to diagnose the issue, and practical tweaks to keep you playing longer with less power loss.

5 months ago

Curing iPhone 14 Plus Charging Port Wear After Daily Fast Charge Cycles

Fast charging can loosen your iPhone 14 Plus port. Learn to spot slow charging and loose cables, then fix it with simple home tricks or long, term prevention.

6 months ago

Xiaomi Mi SmartGlasses 3 Eye Tracking Error Fix

Fix the eye, tracking issue on Mi SmartGlasses 3 with this step, by, step guide to diagnose, clear errors, and restore functionality without repair.

1 year ago

Overcoming Sony X900H Color Saturation Drift During HDR Playback

Discover how to spot and fix color saturation drift on your Sony X900H during HDR playback, tune settings, correct HDR metadata, and keep your scenes vivid and natural.

4 months ago

Remediating Signal Dropout on Bowers & Wilkins PX8 Noise Cancelling Headphones

Discover why the Bowers & Wilkins PX8 may drop sound and how to fix it by tackling interference, low battery, outdated firmware, obstacles and Bluetooth settings for uninterrupted audio

1 week ago

Latest Posts

Fixing the Eufy RoboVac 15C Battery Drain Post Firmware Update

Fix the Eufy RoboVac 15C battery drain after firmware update with our quick guide: understand the changes, identify the cause, and follow step by step fixes to restore full runtime.

5 days ago

Solve Reolink Argus 3 Battery Drain When Using PIR Motion Sensor

Learn why the Argus 3 battery drains fast with the PIR sensor on and follow simple steps to fix it, extend runtime, and keep your camera ready without sacrificing motion detection.

5 days ago

Resolving Sound Distortion on Beats Studio3 Wireless Headphones

Learn how to pinpoint and fix common distortion in Beats Studio3 headphones from source issues to Bluetooth glitches so you can enjoy clear audio again.

6 days ago