Bosch WTG110 Dryer Circuit Board Overheats and Triggers Safety Switch

Understanding the Issue

Bosch dryers are prized for their reliability and quiet operation, but even the most dependable appliances can experience electrical problems. A recent pattern of complaints has emerged from users of the WTG110 model: the internal circuit board begins to overheat and, as a safety measure, triggers the safety switch that shuts the dryer down. This article explains why the board overheats, how the safety switch protects the unit, and what steps you can take to diagnose and fix the problem.

Symptoms to Watch For

If your dryer suddenly stops mid‑cycle and you see a blinking indicator or hear a click from the control panel, you may be dealing with a circuit board overheating. Common signs include:

- The dryer will not start or will turn off shortly after turning on.

- A green or red LED on the control panel flickers or stays on.

- You hear a short “click” when the safety switch activates.

- The dryer’s door stays unlocked after a failed cycle.

- The machine emits a faint smell of burning plastic or electronics.

If you notice any of these, it is important to turn off the dryer immediately and disconnect it from power. Continuing to operate the appliance while the board is overheating can cause permanent damage or create a fire hazard.

What Causes the Circuit Board to Overheat?

1. Excessive Power Demand

The WTG110 relies on a dedicated power supply that feeds a complex control board. If the board is asked to handle more current than it is designed for—perhaps because a component is drawing too much power—the temperature rises quickly. This can be caused by:

- A malfunctioning motor control module.

- A defect in the main relay that allows current to bypass the normal path.

- An overloaded heating element that draws more current than rated.

2. Faulty or Worn Components

Electronic parts, especially capacitors, resistors, and integrated circuits, degrade over time. A bad capacitor can allow excess voltage to pass through, creating a hot spot. Similarly, a faulty MOSFET or transistor can dissipate power inefficiently, turning the board into a small heater.

3. Poor Ventilation

The control board sits in a confined space within the dryer cabinet. If the ventilation holes become clogged with lint or debris, heat can build up. Even a small blockage can reduce airflow enough to keep the board’s temperature above safe limits.

4. External Environmental Factors

If the dryer is placed in a cramped utility closet with no ventilation, ambient heat can add to the board’s temperature. High humidity or dust accumulation can also worsen the situation.

How the Safety Switch Protects the Dryer

Bosch incorporates a thermal fuses or temperature sensors into the control circuit. When the board reaches a critical temperature, the sensor triggers a relay that cuts power to the dryer’s main components. The result is:

- The drum stops rotating.

- The heating element shuts off.

- The dryer’s control panel lights flash or stay lit in a warning state.

- The safety switch stays engaged until the board cools down and the thermostat resets.

This failsafe prevents the dryer from operating in unsafe conditions, protecting both the appliance and the household from fire or electrical hazards.

Diagnostic Steps

Below is a step‑by‑step guide to determine whether overheating is the culprit and to pinpoint the exact fault.

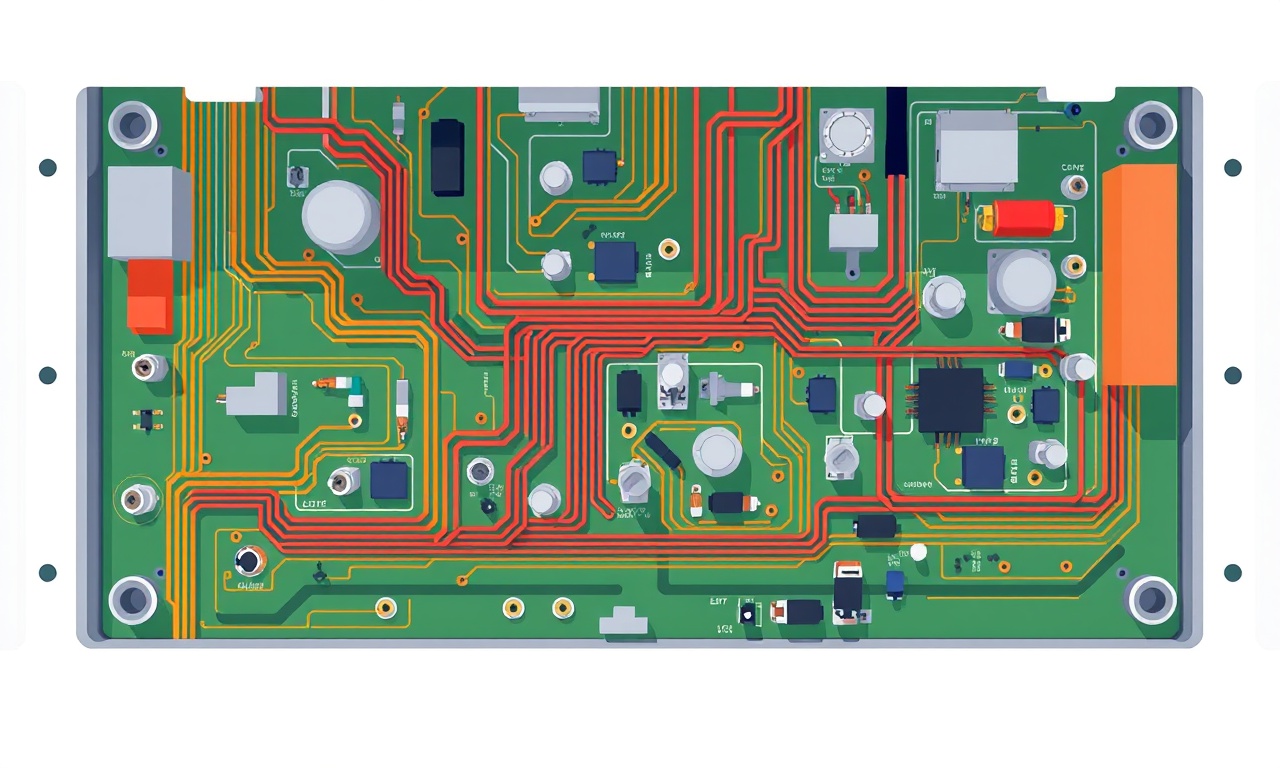

1. Visual Inspection

- Open the dryer cabinet by removing the front panel. Ensure the unit is unplugged.

- Look for scorch marks or melted plastic on the circuit board or surrounding components.

- Check the ventilation: remove lint from the board’s heat sinks and air vents.

- Inspect capacitors: bulging or leaking capacitors indicate failure.

2. Temperature Check

- Re‑connect power and allow the dryer to run a short cycle.

- Use a non‑contact infrared thermometer to measure the board’s surface temperature. A safe operating temperature is typically under 75 °C. Anything above 90 °C suggests overheating.

3. Component Testing

- Test the main relay for continuity and correct operation. A relay that latches or fails to release can let too much current flow.

- Check the MOSFETs (or similar power transistors) for overheating. Replace if necessary.

- Measure resistance across the heating element’s control wires to detect short circuits.

4. Software Diagnostics

Many modern Bosch dryers have an internal diagnostic mode:

- Enter diagnostic mode by pressing a specific sequence of buttons on the control panel (refer to the user manual for exact steps).

- Read error codes: codes that mention “thermal overload,” “board fault,” or “temperature sensor” confirm the issue.

Troubleshooting Common Faults

1. Faulty MOSFET or Transistor

- Symptom: Board overheats during a short cycle; the relay activates repeatedly.

- Fix: Replace the faulty MOSFET with a Bosch‑approved part. Ensure the replacement has identical voltage and current ratings.

2. Bad Capacitor

- Symptom: Visual bulging on the board; power fluctuations.

- Fix: Use a capacitor meter to test ESR (equivalent series resistance). Replace any with a high ESR value.

3. Relay Malfunction

- Symptom: The dryer never starts or shuts off instantly after powering on.

- Fix: Swap the relay with a new unit. Verify that the new relay opens and closes correctly by measuring its coil resistance.

4. Ventilation Blockage

- Symptom: Board temperature rises slowly; no visible component failure.

- Fix: Clean all vents, heat sinks, and the control board’s airflow pathways. Re‑install the front panel and ensure proper clearance.

5. Incorrect Power Supply

- Symptom: Dryer runs fine in one location but overheats in another.

- Fix: Check the mains voltage. If it exceeds the dryer’s rated 240 V, use a voltage regulator or contact your utility company.

Replacing the Circuit Board

If diagnostics confirm that the entire board is damaged, you will need a replacement. Follow these steps:

- Purchase a Bosch WTG110 replacement board from a reputable parts supplier. Verify that the part number matches the model exactly.

- Power down the dryer and unplug it. If you are not comfortable handling electrical components, call a professional.

- Remove the old board: unplug all wires, unscrew mounting brackets, and lift the board out of the cabinet.

- Install the new board: align the screw holes, secure with brackets, and reconnect all wires. Double‑check each connection against the wiring diagram.

- Reassemble the cabinet: replace the front panel and ensure all screws are tightened.

- Run a diagnostic cycle: power on the dryer and use the diagnostic mode to confirm the new board is functioning correctly.

After replacing the board, monitor the dryer’s temperature during the first few cycles. If overheating persists, revisit the diagnostic steps for potential hidden issues.

Preventative Maintenance Tips

Preventing overheating is easier than fixing it. Implement these habits to keep your WTG110 in top shape:

- Regularly clean lint filters: clogged filters reduce airflow and raise internal temperatures.

- Inspect vents: at least once a month, check that the dryer’s vent and cabinet vents are clear of lint.

- Keep the dryer in a well‑ventilated area: avoid stacking objects against the back or sides.

- Test the thermostat: use a multimeter to verify that it reads correctly between 20 °C and 25 °C.

- Schedule professional service: every 3–5 years, have a technician run a full diagnostic.

When to Seek Professional Help

If after following the troubleshooting steps you are still unable to resolve the issue, or if you are uncomfortable with electrical work, contact a licensed appliance repair technician. They can safely diagnose complex electronic problems and guarantee that replacements meet Bosch specifications.

Bottom Line

An overheating circuit board in a Bosch WTG110 dryer is a serious issue that triggers the safety switch to shut the appliance down. Understanding the causes—excess power demand, component failure, ventilation problems, or environmental factors—helps in diagnosing and fixing the problem quickly. By following a systematic diagnostic approach, replacing faulty parts, and maintaining proper airflow, you can keep your dryer running safely and efficiently for years.

Discussion (8)

Join the Discussion

Your comment has been submitted for moderation.

Random Posts

Solving a Persistent Stain Release Issue on Whirlpool WFW5620HW

Tired of spots on your clothes? Discover how to diagnose and fix the stubborn stain release problem on your Whirlpool WFW5620HW with our step-by-step guide.

9 months ago

De'Longhi DL150 Steam Iron Water Recirculation Failure Solution

Trouble with your DeLonghi DL150 steam iron? Learn why water recirculation fails, diagnose the issue, and follow our simple step by step solution to restore steady steam and wrinkle free clothes.

3 months ago

Resolving Lenovo Mirage Solo Bluetooth Pairing Issues

Fix Lenovo Mirage Solo Bluetooth glitches fast with this step by step guide. From simple checks to firmware hacks, reconnect your headset, controllers, and peripherals in minutes.

2 months ago

Lenovo SmartEyewear X Eye Tracking Error Troubleshoot

Get your Lenovo SmartEyewear X eye tracking back with our step-by-step guide. Diagnose glitches, reset settings, and restore smooth gaze navigation quickly.

3 months ago

Calibrating Noise‑Cancellation on Beats Studio Buds

Master Beats Studio Buds ANC: learn the science, step, by, step calibration, and troubleshooting to silence distractions and boost your listening experience.

10 months ago

Latest Posts

Fixing the Eufy RoboVac 15C Battery Drain Post Firmware Update

Fix the Eufy RoboVac 15C battery drain after firmware update with our quick guide: understand the changes, identify the cause, and follow step by step fixes to restore full runtime.

5 days ago

Solve Reolink Argus 3 Battery Drain When Using PIR Motion Sensor

Learn why the Argus 3 battery drains fast with the PIR sensor on and follow simple steps to fix it, extend runtime, and keep your camera ready without sacrificing motion detection.

5 days ago

Resolving Sound Distortion on Beats Studio3 Wireless Headphones

Learn how to pinpoint and fix common distortion in Beats Studio3 headphones from source issues to Bluetooth glitches so you can enjoy clear audio again.

6 days ago